In recent years, people play more and more attention on the magnetic bearing used in blower industry. To compare with the traditional bearing, magnetic bearing has no contact, no lubrication, energy efficient, suitable for the extreme environments such multiple advantages, to injected new vitality to the innovation and development of the blower industry. As China's urban sewage treatment capacity rising, energy efficient water treatment equipment development in full swing, from the Roots blower, high-speed single-stage centrifugal blowers, air blowers to today's turbo blower, the update and development of these products illustrate urgent demand on the market for energy-saving and environmental protection products.

FG-AMB was established in August 2012, is a China & Korea Joint Venture Company specialized in the research and development, production and marketing of active magnetic bearing(AMB) and its relevant products. The R&D team of FG-AMB began to research the active magnetic bearing and its relevant products since 2000. Though more than 10 years’ accumulation, FG-AMB already have a wealth of research experience in the field of active magnetic bearing and fully mastered the key technology of active magnetic bearing system and its relevant products. With a wealth of research and development experience, strong capability of independent innovation, increasingly comprehensive before and after sales service, we leap into the front ranks of the peer in China, and become one of the few companies equipped with the full capacity for researching and developing the active magnetic bearings in the world at present.

FG-AMB turbo blower product release

December 23th, 2015, FG-AMB held the turbo blower release conference in Foshan China. More than 100 leaders from government, the environmental protection department, and users from Korea, engineer companies, dealers and the media attended the conference. Witness this latest product which with high-tech background, take root in China.

In the conference, Mr. Kim from FG-AMB sales department comprehensive introduce the performance of the turbo blower. He mentioned that even though FG-AMB has established only three years, however the Korean R&D team of FG-AMB has more than 10 years researching experience on the active magnetic bearing field. They have successfully developed the AMB IGT spindle and the world’s first mag-lev system for R2R processing before the turbo blower, and provided the active magnetic bearing research service for POSCO, Samsung, Hyundai, NUAA etc.

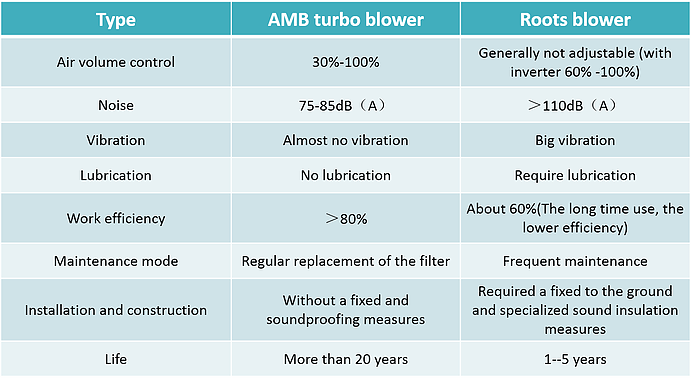

This AMB turbo blower is an innovative product which successfully developed based on the Korea profound technical strength. It is a new type of energy-saving and environmentally friendly product which uses active magnetic bearing and high-speed permanent magnet system motors technology and integrated design. This product has several core components: active magnetic bearing, fluid dynamics impeller, efficient inverter, high-speed permanent magnet motor and control system.

Product advantages:

The active magnetic bearing system is adopted without abrasion and in no need of lubrication of maintenance.

The three-dimensional flow design method is adopted and high strength aluminum alloy impeller processed by 5-alxe precision machine tool integration to maximize the working efficiency of radial impeller and improve the service life of the impeller.

High-performance frequency converter is adopted to control the revolving speed and multiple control modes are available for choice.

The advanced control system is adopted to monitor the operating status and is able to conduct remote control and there is no need to designate personnel for guarding.

Fully enclosed water cooling system and air cooling system are employed for heat dissipation of blower so as to guarantee the air blower stays at a stable and highly efficient operating status.

Fully enclosed water cooling system and air cooling system are employed for heat dissipation of blower so as to guarantee the air blower stays at a stable and highly efficient operating status.

The motor adopts directly connected drive which is small and light to save space occupation.

Low manufacturing costs and maintenance costs, timely after-sale service.

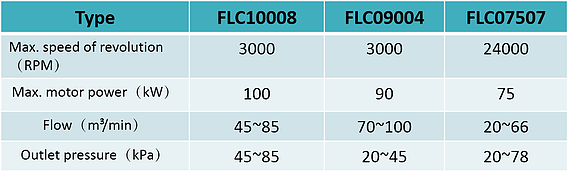

FG-AMB turbo blower parameter

FG-AMB won several patent like: the US patent, Korea patents etc. The company also has the ISO9001 certification and CE. Now the turbo blower has passed the test of the mechanical industrial blower product quality supervision, fluid efficiency reaches 82.99%, to compare with traditional blower the efficiency improved by 15~40%. Otherwise, AMB turbo blower’s stability is better than air blower, because it will produce friction between the rotatable shaft with the surrounding bearings when the machine turn on or turn off. When the air blower in runtime, the rotational accuracy is 10μm, there are no fitting device in the market suitable for such a small gap. It will cause damage to the blower when the impurities came in.

The rotational accuracy of AMB turbo blower is 500μm, it can solve this fitting difficult problem. Currently, the FLC10008 turbo blower has been put into use in Korea POSCO in June 2014 and Foshan Yanbu sewage water treatment plant in October 2015.

A strong R&D team

In the conference, every participants were looking forward to this new product. They have the problems on the performance, technology advantages, maintenance, special product development of the turbo blower. Dr. Choi Sang Hyun of FG-AMB answered these questions one by one, in the same time participants can learned more about the company's Korean technology background. Design and develop the magnetic bearing system should use the mechanical design, testing technology, DSP control technology, electromagnetic design technology and other core technology, that require an integrated multi-disciplinary and experienced R & D team. Actually, there are few company can own such a R&D team in the world. FG-AMB has such a strong independent Korea R&D team which have wealthy research and development experience on active magnetic bearing, rotating machinery design, manufacturing systems, control systems and other disciplines. Dr. Choi Sang Hyun is the leader of this team, he professional in the rotor dynamics, mechanical. He uses to be the special researcher of Seoul National University turbine power machinery research center, and the special scholars engaged in research work in Germany. He engaged in design and research work in the world’s famous rotating machinery companies like: ABB, Atlas Copco etc. Dr. Choi has been engaged in the research work on rotating machinery and magnetic bearing system during 10 years working for the D&M Technology Ltd. which is a famous magnetic bearing company in Korea.

The company mastered the core technology magnetic bearings, not only successfully be applied in the development of AMB turbo blower, but also done a lot of research and development in various fields like: semiconductor industry; Mag-lev system for R2R processing in printed electronic industry; ORC turbine in energy industry; High-speed motor of NUAA; Milling motorized spindle system of HUST; Turbo molecular pump of JE-IL Vacuum; Nano-spindle of POSCO; Refrigerant compressor of Samsung; High-speed switched reluctance motor etc.

Now, FG-AMB turbo blower has 100kW, 90kW, 75kW three types, the company has make the future development plans. They plan to develop the 150kW and 300kW in 2016, develop the full range of 75~500kW turbo blower in 2017, develop the 100kW stage compressor in 2018.

Sewage water treatment plant site visits

In the afternoon, all the participants came to Foshan Yanbu sewage treatment plant. They visited the blower room and investigate the FG-AMB turbo blower operational state.

This plant used 5 sets roots blower (2sets use, 3sets spare), the actual operating power of each blower is 51Kw, flow 32 m³/min, noise is usually more than 110dB, the blower need to overhaul every month, each blower covers an area of 6.73㎡. These 5 sets roots blower have been used in turn for 7 years, the unit performance declining year by year, the motor temperature alarm too high usually, so the roots blower can’t run at the design frequency speed (50Hz), can only be run at low speed frequency (40Hz). In October this year, this plant use FLC10008 turbo blower to instead of the roots blower, the power of FG-AMB is 70Kw, noise is 80dB, every blower only covers an area of 3.6㎡.

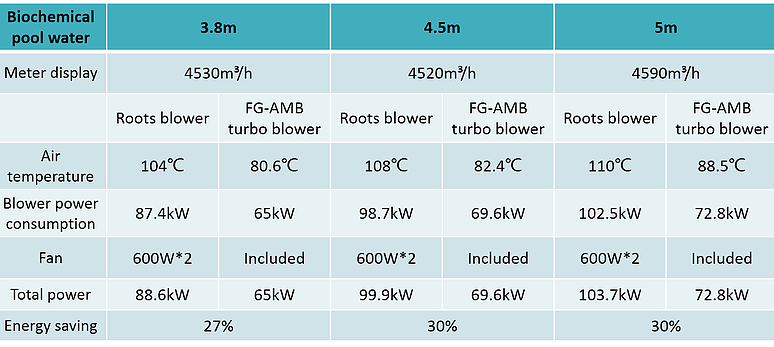

Roots blower and AMB turbo blower actual operation confrontation

Under a certain pressure, the air temperature is higher, density will be lower; At this point, even though the meter display show that the volume flow of blower is the same, actually the output air temperature of AMB turbo blower will lower than the roots blower, so that the air mass flow rate output will be greater than roots blower.

Installation Maintenance contrast

To compare with the roots blower, the turbo blower save 30~40%( The higher the water level, the closer to the design point 8m level, more energy saving) .The annual electricity savings 100kW × 24 hours × 360 days × 30% = 26 million kWh , the annual electricity savings by RMB 1 / calculation, the annual electricity savings of RMB 260,000, saving maintenance costs RMB 20,000 / year, the total cost savings of RMB 280,000.

Advantages and company vision

At the end of the conference, Mr. Choi Imsaeng the CEO of FG-AMB mentioned that: As a China & Korea Joint Venture Company, we committed to provide the international forefront magnetic bearing technology, provide the highest quality products and services, such as: core machine promised three-year warranty, quickly respond within 3 hours after receive customer feedback, provide the maintenance service in 3 days. Turbo blower unified sales in domestic and provide after-sale service, ensure its product development costs and production costs are lower than imported products. Take 100kW for example, customer uses 1 set AMB turbo blower save 35000 kW/h electricity saving every year of 20 million/year, reduce carbon dioxide of nearly 300 tons/year. FG-AMB hopes that they can sell or install 1000 sets turbo blower in China in next five years, it can save 350 million kW/h electricity savings of 200 million yuan/year, reducing carbon dioxide of nearly 300,000 tons / year. Mr. Choi Imsaeng vision: We are committed to China's industrial energy conservation, to develop the most scientific and technological content of magnetic bearing products and services to all types of energy-saving and environmental protection fields, continues to contribute ourselves to the environmental protection cause of human society.